E-mail: novotek@novotek.co

Quality Policy

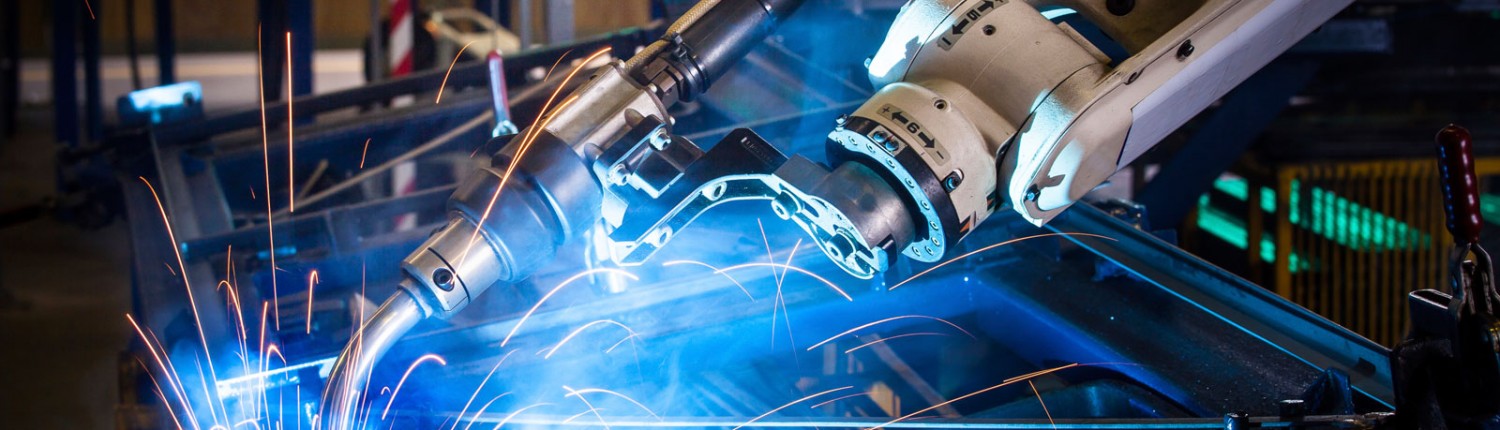

Our Quality Management System includes an intense process for all of our parts to be inspected and monitored throughout the manufacturing process. This involves material treatment, fabrication, etc. and keeping details records.

Upon final assembly, Novotek Machines also performs rigorous testing on each product. Actual operating conditions are simulated as closely as possible to thoroughly examine all components for performance, durability and reliability.

Superior quality of our parts and units as well as our customer service is Novotek Machines’ top priority.Upon final assembly, Novotek Machines also performs rigorous testing on each product. Actual operating conditions are simulated as closely as possible to thoroughly examine all components for performance, durability and reliability.

Novotek Quality Management in Each Production Process:

1. Pre-scheduled raw material inspections

2. Pre-scheduled outsourced components inspections

3. Ensured compliance to customer/association project specifications

4. During manufacturing, each stage has at least one Quality Management Supervisors

5. Final product meets related international certifications: such as CE, etc.

6. Production testing and reporting

7. Loading and shipment tracking system

8. Installation and commissioning compliance

9. Training and operation compliance

2. Pre-scheduled outsourced components inspections

3. Ensured compliance to customer/association project specifications

4. During manufacturing, each stage has at least one Quality Management Supervisors

5. Final product meets related international certifications: such as CE, etc.

6. Production testing and reporting

7. Loading and shipment tracking system

8. Installation and commissioning compliance

9. Training and operation compliance